Swedish engineers have improved the process through which hydrogen fuel is produced from solar electricity by 800%.

Hydrogen fuel is considered one of the best renewable alternatives to fossil fuels in heavy machinery like planes and ships, but its creation requires electricity.

That electricity can be from renewable sources like solar or wind, but the efficiency is limited. Now, according to researchers at Linköping University, a combination of materials has greatly improved the ability to generate hydrogen with solar energy.

The research team has previously shown that a material called cubic silicon carbide (3C-SiC) has beneficial properties for facilitating the reaction where water is split into hydrogen and oxygen. The material can effectively capture the sunlight so that the energy therein can be used for hydrogen production through the photochemical water splitting reaction.

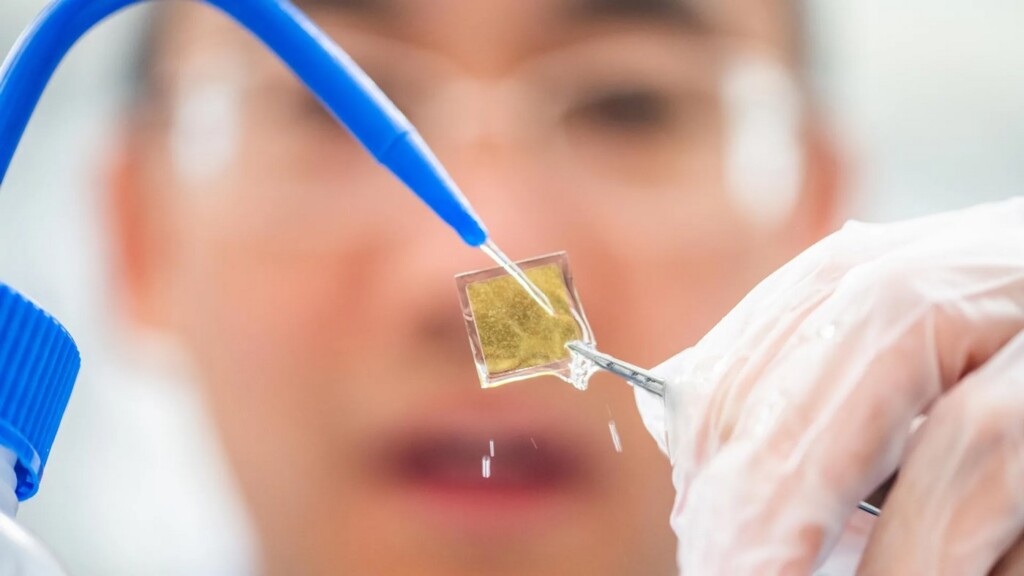

In their current study, the researchers have further developed a new combined material consisting of three layers: a layer of cubic silicon carbide, a layer of cobalt oxide and a catalyst material that helps to split water.

“Passenger cars can have a battery, but heavy trucks, ships or aircraft cannot use a battery to store the energy. For these means of transport, we need to find clean and renewable energy sources, and hydrogen is a good candidate,” says Jianwu Sun, associate professor at Linköping University, who has led the study published in the Journal of the American Chemical Society.

“It’s a very complicated structure, so our focus in this study has been to understand the function of each layer and how it helps improve the properties of the material. The new material has eight times better performance than pure cubic silicon carbide for splitting water into hydrogen,” says Sun.

When sunlight hits the material, electric charges are generated, which are then used to split water. A challenge in the development of materials for this application is to prevent the positive and negative charges from merging again and neutralizing each other.

OTHER GREEN HYDROGEN REPORTS: French Company Discovers Massive Reserve of Clean Hydrogen Gas that Could Start Renewable Revolution

In their study, the researchers show that by combining a layer of cubic silicon carbide with the other two layers, the material becomes more able to separate the charges, thereby making the splitting of water more effective.

Almost all hydrogen present on the market is “grey” hydrogen produced from a fossil fuel. The production of one ton of “grey” hydrogen gas causes emission of up to ten tons of carbon dioxide. “Green” hydrogen is produced using renewable electricity as a source of energy.

The long-term goal of the Linköping University researchers is to be able to use only energy from the sun to drive the photochemical reaction to produce “green” hydrogen.

HYDROGEN DEVELOPMENT: Hydrogen Gas Blend Will Reduce Power Plant’s Emissions by 75%–as it Helps Power 6 States

Most materials under development today have an efficiency of between 1% and 3%, but for commercialization of this green hydrogen technology the target is 10% efficiency. Being able to fully drive the reaction using solar energy would lower the cost of producing green hydrogen, compared to producing it using supplementary renewable electricity as is done with the technology used today.

Jianwu Sun speculates that it may take around five to ten years for the research team to develop materials that reach the coveted 10% limit, but they’re off to a flying start.

SHARE This Big Potential Breakthrough With Your Friends Concerned About The Climate…