Researchers at MIT have developed a novel method to produce sustainable green hydrogen using recycled aluminium and seawater, a breakthrough that promises dramatically lower emissions and cost compared to traditional methods.

{alcircleadd}

Conventional hydrogen production relies heavily on steam methane reforming, which emits 9-12 kg of CO₂ per kg of hydrogen, far from climate-friendly. Even “green” hydrogen via solar or wind-powered electrolysis remains resource-intensive and expensive.

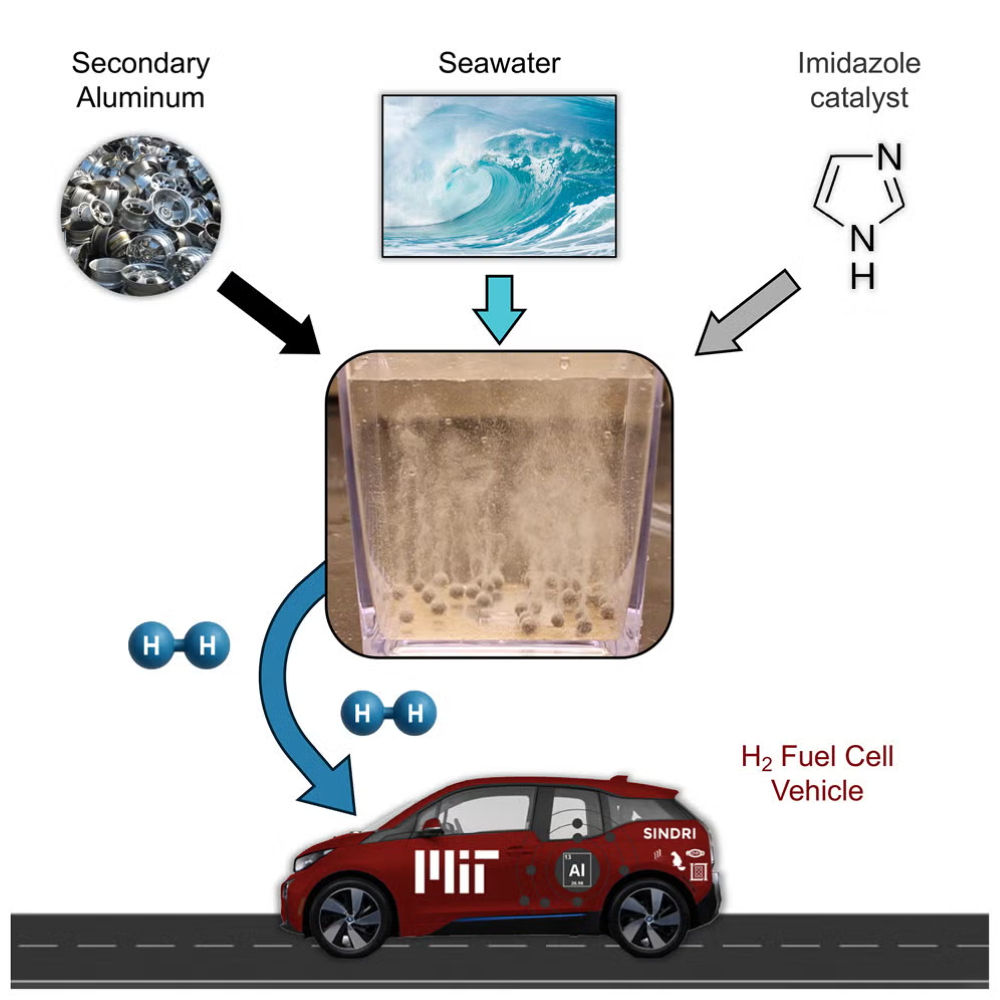

MIT’s innovative method harnesses the aluminium-water reaction (AWR), when aluminium reacts with water, it generates hydrogen, heat and aluminium oxyhydroxide. Aluminium’s abundance and high energy density (twice that of diesel by volume) make it an appealing feedstock.

“We were explaining the science of this process in conferences, and the questions we would get were, ‘How much does this cost?’ and, ‘What’s its carbon footprint?’” said Aly Kombargi, a lead author of the study who earned his Ph.D. in mechanical engineering from MIT.

The challenge lies in the natural oxide layer that forms on aluminium, preventing water from reacting. MIT overcame this by coating recycled aluminium pellets with a gallium–indium alloy, effectively removing the oxide barrier and enabling continuous reaction with seawater.

A full life-cycle assessment using MIT’s Earthster tool found that this process emits just 1.45 kg CO₂ per kg of H₂, close to the cleanest electrolysis systems and far better than fossil-based methods. Cost estimates use a price of about USD 9.20 per kg of hydrogen, comparable to other green hydrogen paths.

Notably, the process also yields boehmite, a valuable aluminium oxide used in semiconductors and industrial applications. Projected boehmite sales could quintuple profitability, making the process economically promising.

MIT researchers demonstrated a prototype “hydrogen reactor” the size of a water bottle, capable of fueling an electric bicycle for hours. Future versions could power small boats or underwater vehicles, drawing only on seawater and aluminium pellets, ideal for off-grid or remote applications.

This method offers safety and logistical advantages; instead of handling pressurised hydrogen gas, the system transports solid aluminium pellets, releasing hydrogen on demand at the destination. The gallium–indium alloy activator can be recovered and reused, enhancing sustainability.

Using recycled aluminium, requiring just 5 per cent of the energy needed for primary production, helps slash emissions dramatically. With cleaner smelting and transport options, emissions could be further reduced by up to 25 per cent.

The research builds upon earlier experimental work by the MIT team, which explored the potential of aluminium, seawater and even caffeine as inputs for hydrogen generation. That initial study laid the groundwork for the current findings.

“We’re in the ballpark of green hydrogen,” Kombargi said. “This work highlights aluminium’s potential as a clean energy source and offers a scalable pathway for low-emission hydrogen deployment in transportation and remote energy systems.”

The research team is working on scaling and field-testing the system for transportation, remote energy and marine uses. If successful, this aluminium‑to‑hydrogen pathway could offer a cost-effective, low‑emission fuel option, transforming scrap metal and seawater into clean energy wherever infrastructure is limited.

Information and image credit: https://www.thebrighterside.news/